●Sintered NdFeB maganadisoAn yi amfani da su sosai don kyawawan kaddarorin su. Koyaya, ƙarancin juriyar lalata da maganadisu yana hana su ci gaba da amfani da su a aikace-aikacen kasuwanci, kuma suturar saman ta zama dole. Abubuwan da ake amfani da su da yawa a halin yanzu sun haɗa da electroplating Ni-tushen coatings, electroplating Zn- tushencoatings, kazalika da electrophoretic ko fesa epoxy coatings. Amma tare da ci gaba da ci gaba na fasaha, abubuwan da ake buƙata don suturaof NdFeBHar ila yau, suna karuwa, kuma na al'ada electroplating yadudduka wani lokacin ba zai iya biyan bukatun. Rufin tushen Al da aka ajiye ta amfani da fasahar tururi ta jiki (PVD) tana da kyawawan halaye.

● Dabarun PVD irin su sputtering, ion plating, da evaporation plating duk na iya samun suturar kariya. Tebu 1 ya lissafa ƙa'idodi da halaye kwatanta na electroplating da sputtering hanyoyin.

Tebura 1 Halayen kwatance tsakanin electroplating da hanyoyin sputtering

Sputtering wani al'amari ne na yin amfani da barbashi masu ƙarfi don jefa bama-bamai a kan wani ƙaƙƙarfan ƙasa, yana haifar da atom da ƙwayoyin halitta a kan ƙaƙƙarfan farfajiya don musayar makamashin motsa jiki tare da waɗannan barbashi masu ƙarfi, ta yadda za su fantsama daga ƙasa mai ƙarfi. Grove ne ya fara gano shi a shekara ta 1852. Dangane da lokacin ci gabansa, an sami sputtering na biyu, manyan sputtering, da sauransu. Duk da haka, saboda rashin iyawar sputtering da wasu dalilai, ba a yi amfani da shi ba har zuwa 1974 lokacin da Chapin ya ƙirƙira daidaitaccen sputtering magnetron, wanda ya sa saurin gudu da ƙananan zafin jiki ya zama gaskiya, kuma fasahar magnetron sputtering ta sami damar haɓaka cikin sauri. Magnetron sputtering hanya ce ta sputtering wanda ke gabatar da filayen lantarki yayin aikin sputtering don haɓaka ƙimar ionization zuwa 5% -6%. An nuna zane-zanen madaidaicin sputtering magnetron a cikin hoto 1.

Hoto 1 Tsarin ƙa'ida na daidaitaccen sputtering magnetron

Saboda da kyau kwarai lalata juriya, Al shafi ajiye taion tururiAjiye (IVD) Boeing ya yi amfani da shi azaman madadin CD ɗin lantarki. Lokacin amfani da sintered NdFeB, galibi yana da fa'idodi masu zuwa:

1.High ƙarfin mannewa.

Ƙarfin mannewa na Al daNdFeBshine gabaɗaya ≥ 25MPa, yayin da manne ƙarfi na talakawa electroplated Ni da NdFeB ne game da 8-12MPa, da kuma m ƙarfi na electroplated Zn da NdFeB ne game da 6-10MPa. Wannan fasalin yana sa Al/NdFeB ya dace da kowane aikace-aikacen da ke buƙatar ƙarfin mannewa. Kamar yadda aka nuna a cikin hoto 2, bayan canza yanayin 10 na tasiri tsakanin (-196 ° C) da (200 ° C), ƙarfin mannewa na murfin Al ya kasance mai kyau.

Hoto na 2 na Al/NdFeB bayan 10 madaidaicin tasirin keke tsakanin (-196 ° C) da (200 ° C)

2. Jiƙa a manne.

Rufin Al yana da hydrophilicity kuma kusurwar lamba na manne kadan ne, ba tare da haɗarin fadowa ba. Hoto na 3 yana nuna 38mN samanruwa tashin hankali. Ruwan gwajin ya bazu gaba daya a saman murfin Al.

Figure 3. gwajin 38mN samantashin hankali

3.The Magnetic permeability na Al ne sosai low (dangantacciyar permeability: 1.00) kuma ba zai haifar da garkuwa da Magnetic Properties.

Wannan yana da mahimmanci musamman a cikin aikace-aikacen ƙananan ƙararrawa a cikin filin 3C. Ayyukan saman yana da mahimmanci. Kamar yadda aka nuna a cikin Hoto 4, don ginshiƙin samfurin D10 * 10, tasirin Al shafi akan kaddarorin maganadisu kaɗan ne.

Hoto 4 Canje-canje a cikin kaddarorin maganadisu na sintered NdFeB bayan saka PVD Al shafi da kuma sanya murfin NiCuNi electroplating a saman.

4.The uniformity na kauri ne mafi alhẽri

Domin an ajiye shi a cikin nau'i na kwayoyin halitta da kuma gungu na atomic, kauri na Al shafi yana da iko gaba daya, kuma daidaito na kauri ya fi na kayan lantarki. Kamar yadda aka nuna a cikin hoto na 5, murfin Al yana da kauri iri ɗaya da kyakkyawan ƙarfin mannewa.

HotoSashin giciye na 5 na Al/NdFeB

5.The PVD fasahar jijiya tsari ne gaba daya m muhalli da kuma babu wani muhalli gurbatawa matsala.

Dangane da buƙatun buƙatu masu amfani, fasahar PVD kuma na iya ajiye abubuwa masu yawa, irin su Al / Al2O3 multilayers tare da kyakkyawan juriya na lalata da kayan kwalliyar Al / AlN tare da kyawawan kaddarorin inji. Kamar yadda aka nuna a cikin Hoto 6, tsarin giciye na Al / Al2O3 multilayer shafi.

Fgiwa 6Ketare sasheda Al/Al2O3 masu yawa

A halin yanzu, manyan matsalolin da ke hana masana'antu na Al coatings akan NdFeB sune:

(1) An ajiye gefuna shida na maganadisu daidai gwargwado. Abubuwan da ake buƙata don kariyar maganadisu shine a saka madaidaicin sutura a saman farfajiyar maganadisu, wanda ke buƙatar warware jujjuya mai girma uku na maganadisu a cikin sarrafa tsari don tabbatar da daidaiton ingancin sutura;

(2) Al shafi tsiri tsari. A cikin babban tsarin samar da masana'antu, babu makawa cewa samfuran da ba su cancanta ba zasu bayyana. Sabili da haka, wajibi ne don cire murfin Al mara kyau kumasake karewashi ba tare da lalata aikin maganadisu na NdFeB ba;

(3) Dangane da takamaiman yanayin aikace-aikacen, maganadisun NdFeB da aka lalata suna da maki da siffofi da yawa. Don haka, wajibi ne a yi nazarin hanyoyin kariya masu dacewa don nau'o'i da siffofi daban-daban;

(4) Haɓaka kayan aikin samarwa. Tsarin samarwa yana buƙatar tabbatar da ingantaccen samarwa mai dacewa, wanda ke buƙatar haɓaka kayan aikin PVD wanda ya dace da kariyar maganadisu ta NdFeB kuma tare da ingantaccen samarwa;

(5) Rage farashin samar da fasahar PVD da haɓaka gasa ta kasuwa;

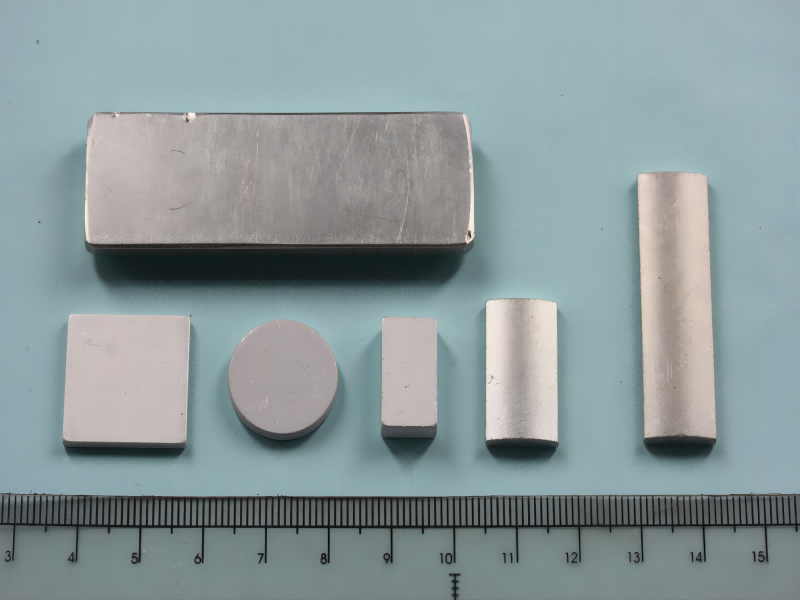

Bayan shekaru na bincike da ci gaban masana'antu. Fasahar wutar lantarki ta Hangzhou Magnet ta sami damar samar da samfuran PVD Al mai yawa ga abokan ciniki. Kamar yadda aka nuna a Hoto na 7, Hotunan samfur masu dacewa.

Hoto 7 Al mai rufi NdFeB maganadiso tare da siffofi daban-daban.

Lokacin aikawa: Nuwamba-22-2023